Low-Stress Abrasion-Corrosion of High-Cr White Cast Iron

Overview

High chromium white cast irons are commonly used in applications that require abrasion and corrosion resistance. They are known to have the corrosion resistance of stainless steels, and excellent wear resistance due to the presence of carbides in their microstructure. They can be named as “wear-resistant stainless steel.”

Many studies aim to improve their wear or corrosion resistance. Currently, multiple microstructural modifications are carried out during manufacturing these alloys to improve their lifetime. The challenge is that these alloys not only should have outstanding corrosion and abrasion characteristics but also have to resist conjoint action of abrasion and corrosion, i.e., tribocorrosion. While carbide precipitates improve wear resistance of these alloys may have adverse effects on their localised and tribo- corrosion behaviour of these alloys.

Assessing tribocorrosion behaviour of these, often, multiphase alloys is not a trivial task. Hence, most industry practices are focused on individual corrosion and abrasion properties rather than their combined action. Likewise, the fact these alloys are multiphase further complicates their assessment. Tribo-electrochemical methods proved as powerful tools in investigating tribocorrosion behaviour of single-phase alloys such as stainless steels. Often, however, they are only beneficial for single-phase alloys and when the alloy is not prone to localised corrosion. Combination of localised and tribo-corrosion mechanism complicates the current response.

Objective

The objective of this work was to differentiate the individual effects of localised corrosion and abrasion-corrosion occurring on the high-Cr WCI multiphase alloy. We investigated the effects of round and semi-angular coarse abrasive particles on the three-body abrasion-corrosion of these materials in a moderately alkaline solution with and without chloride ions. Electrochemical techniques, including potentiostatic polarisation and zero resistant amperometry, were employed. Scanning electron microscopy (SEM) and focused ion beam (FIB) methods were, then, used to analyse the worn surfaces and to gain a better understanding of the subsurface deformation and localised dissolution.

Why is it important?

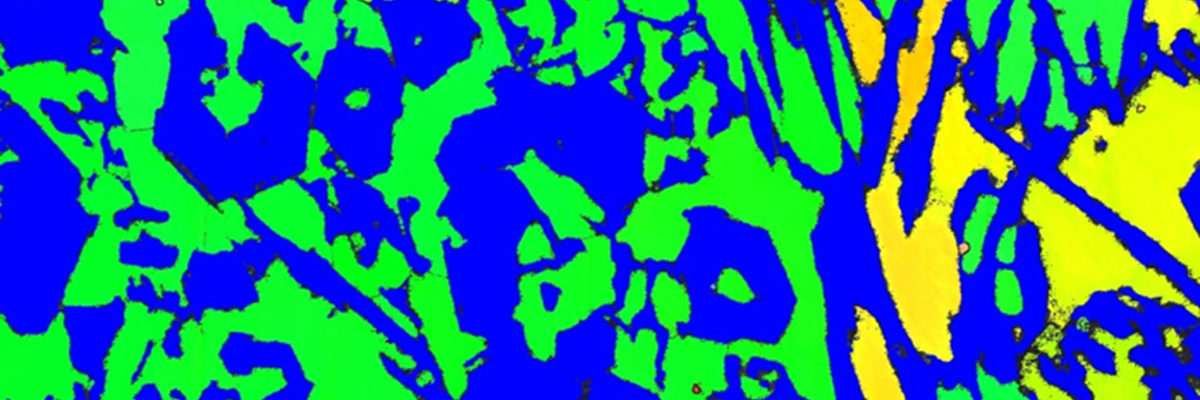

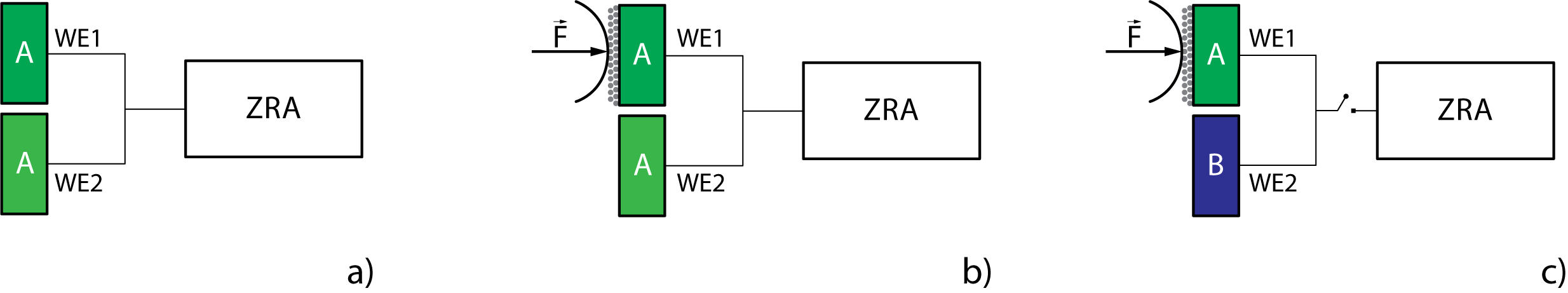

Conventionally, electrochemical noise studies using ZRA involve galvanically coupling two nominally identical electrodes (Figure 1a). This arrangement has been extensively used to monitor localised corrosion incidents; i.e. nucleation, termination or stable growth of the pits and to determine critical pitting temperature. The polarity of the transients indicate whether localised dissolution is occurring on the WE1 or WE2; e.g. as per the most common polarity convention, a negative current transient indicates dissolution activity on the WE2.

In a tribocorrosion experiment, the WE1 undergoes abrasion-corrosion, whereas the identical secondary electrode WE2 is subjected to corrosion-only (Figure 1b). Using a ZRA on such an arrangement, information can be obtained on the effects of wear on passive film removal and reformation mechanisms. For example, under abrasion, an increase in the current measured indicates disruption of the passive oxide film. Post abrasion, film repair is generally associated with a rapid current decay similar to those of scratch tests.

A frequent problem with the setup shown in Figure 1b is the occurrence of current polarity reversals when both WE1 and WE2 undergo localised corrosion. Polarity reversal makes the interpretation of the results difficult. Since it is known that localised corrosion susceptibility of the high-Cr WCI is due to a weakened passivity at the carbide/matrix interface using a single-phase alloy as WE2 would alleviate its localised corrosion vulnerability, and is, therefore, polarity reversal problems. Thus, the electrode arrangement schematically shown in Figure 1c was used in this study.

Figure 1; a) Conventional ZRA measurement in a corrosion-only condition, the two electrodes are identical, b) abrasion-corrosion ZRA test with two identical electrode materials, c) modified ZRA measurement, dissimilar electrode materials with similar passivity were used; in b & c) WE1 undergoes abrasion while WE2 is subjected to corrosion-only.

Figure 1; a) Conventional ZRA measurement in a corrosion-only condition, the two electrodes are identical, b) abrasion-corrosion ZRA test with two identical electrode materials, c) modified ZRA measurement, dissimilar electrode materials with similar passivity were used; in b & c) WE1 undergoes abrasion while WE2 is subjected to corrosion-only.

The modified ZRA method, in combination with cyclic and potentiostatic polarization and surface characterisation techniques, revealed the three-body abrasion-corrosion mechanism and post abrasion interfacial corrosion susceptibility of these alloys:

- In the absence of chloride ions, abrasion-corrosion of high-Cr WCI by both CB and semi-angular SiSa particles resembled the well-documented behaviour of the single-phase austenitic 316L SS.

- In the presence of chloride ions, once abrasion-corrosion reached steady state, SiSa particles increased the net anodic current, i.e., from 3.84 μA vs. 0.42 μA, compared to that of the chloride-free solution.

- The ZRA abrasion-corrosion study of the multiphase high-Cr WCI showed that the angularity of particles might alter the post-abrasion interfacial corrosion vulnerability of the material. Semi-angular silica sand abrasives had a more significant adverse impact on the post-abrasion interfacial corrosion susceptibility than those of round ceramic beads. Any material developed for tribocorrosive conditions should account for the angularity of particles and their subsequent effects on localised corrosion behaviour.

Get the article

M. Salasi, M. Iannuzzi, W. Rickard, Z. Quadir, Journal of The Electrochemical Society 166, 13 (2019): p. C382-C393. doi: 10.1149/2.0511913jes

M. Salasi, M. Iannuzzi, W. Rickard, Z. Quadir, Journal of The Electrochemical Society 166, 13 (2019): p. C382-C393. doi: 10.1149/2.0511913jes

Citation

Salasi, M., et al., “Low Stress Abrasion-Corrosion of High-Cr White Cast Iron: Combined Effects of Particle Angularity and Chloride Ions,” Journal of The Electrochemical Society, Vol. 166, No. 13, 2019, pp. C382-C393.

https://doi.org/10.1149/2.0511913jes.

Copyright etc.

The article has been published as OpenAccess, distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.