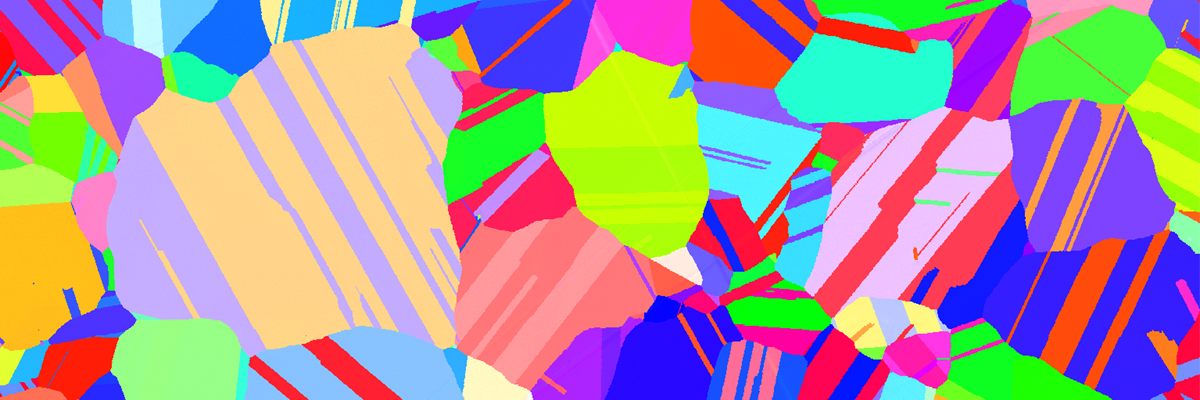

The Role of Nano-thin Intergranular Phases on Nickel Alloy 725 Brittle Failure

Overview

Precipitation hardened nickel alloy (UNS N07725) has been considered one of the most reliable materials for oil and gas subsea production. However, specific batches that meet the current regulations had failed due to hydrogen embrittlement. Concerningly, the microstructural feature(s) that embrittled the materials was not identified. In our previous publications, we discovered that a failed batch presented an abundant intergranular formation of the brittle and nano-thin F phase. As the studied alternative commercial batches showed a negligible amount of F phase, it was suggested that the precipitate could compromise the performance of the alloy in service conditions.

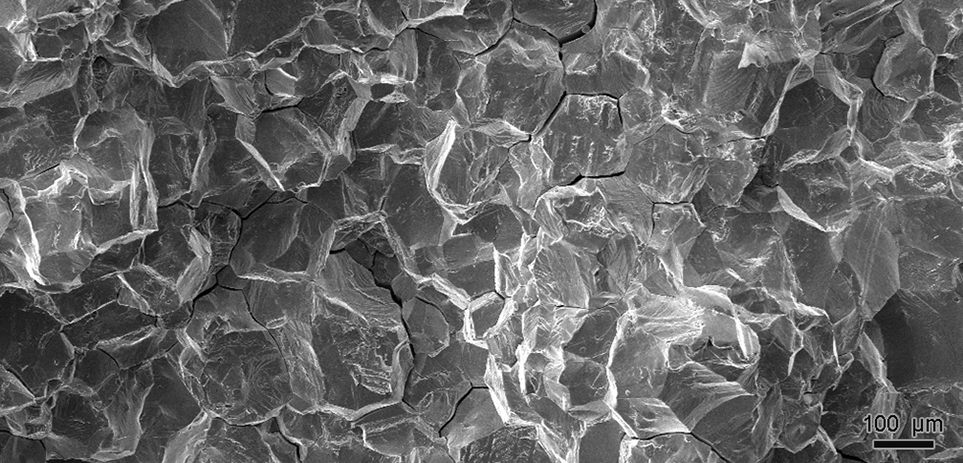

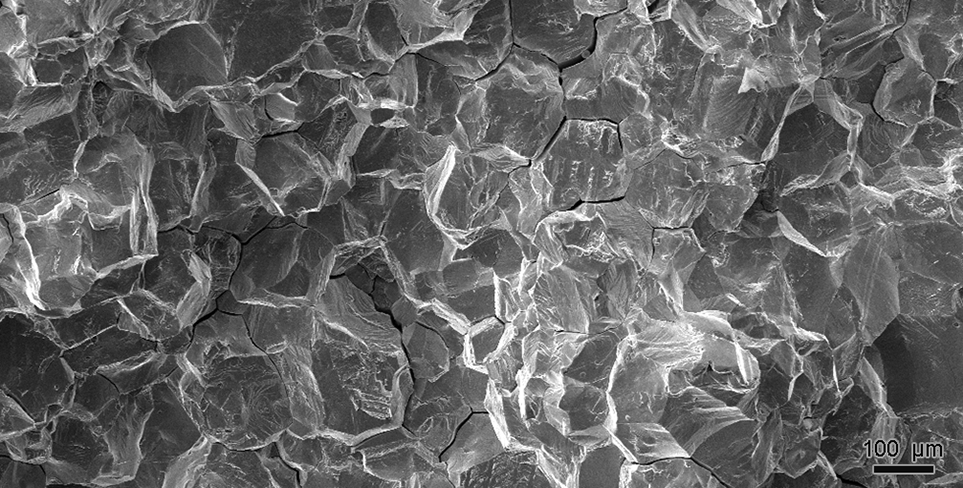

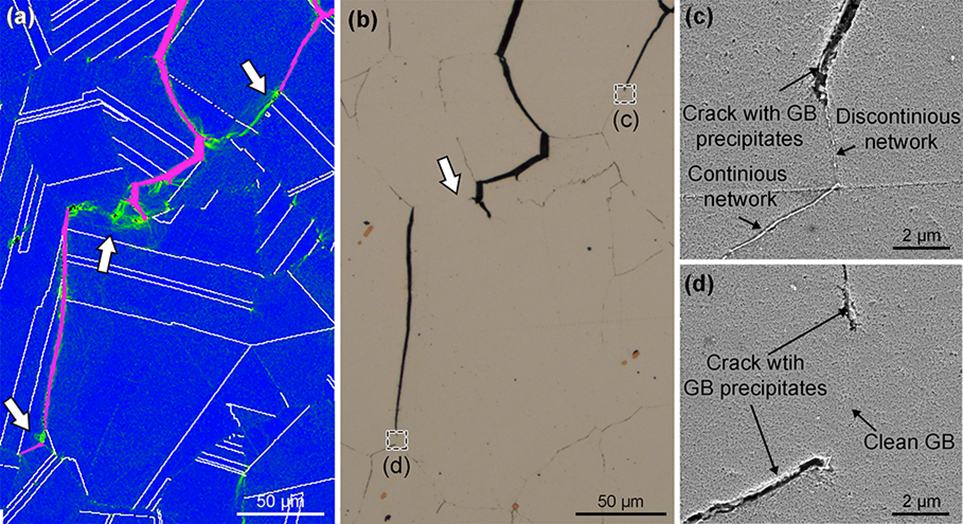

Figure 1. Intergranular fracture surface of failed nickel alloy 725.

Objectives

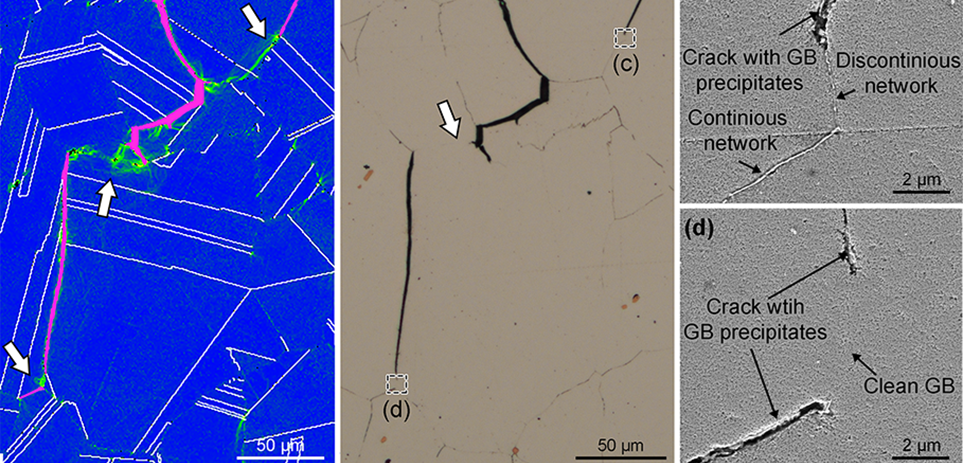

In this investigation, we evaluated the role of F phase in assisting the crack propagation of the failed batch. We found that the continuous F phase network offered a low energy path for crack opening by matrix-precipitate interfacial decohesion.

Figure 2. Crack advance analysis. (a) EBSD map showing in crack cross-section shape in pink and deformation areas in green. (b) Optical and (c-d) SEM images of intergranular precipitates occurrence around the crack cross-section. White arrows indicate arresting locations, which correspond to precipitate free or partially decorated grain boundaries.

Why is it important?

The link between the alloy's microstructure and hydrogen embrittlement susceptibility enables the development of resistant materials. For instance, thermomechanical processing can be optimized to minimize the extent of the detrimental F phase and enhance the properties of the alloy. Additionally, we can design new qualification tests to detect and avoid the service of susceptible nickel alloys.

Get The Paper!

Citation

M.S. Hazarabedian, M. Iannuzzi, The Role of Nano-sized Intergranular Phases on Nickel Alloy 725 Brittle Failure, npj Mater. Degrad. 5 (2021) 39. http://doi.org/10.1038/s41529-021-00185-2