Expertise

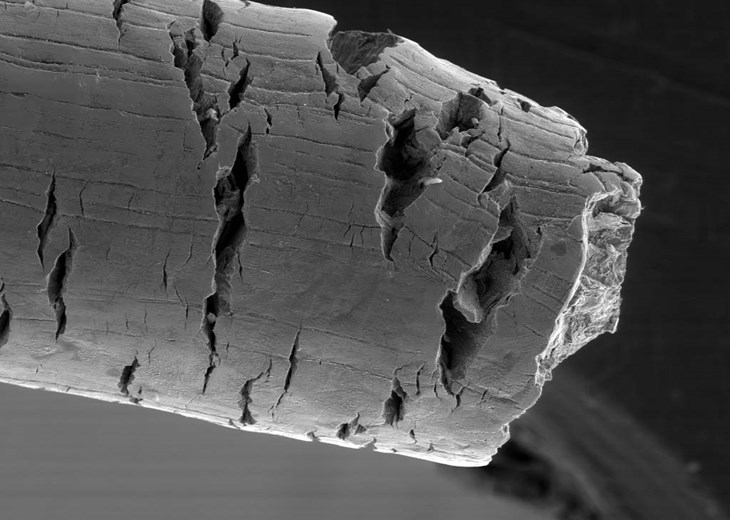

Mechanically Assisted Corrosion

Mechanically assisted corrosion (MAC) encompasses the most dangerous forms of corrosion, including stress corrosion cracking, corrosion fatigue, tribocorrosion, and the various types of hydrogen embrittlement.

At the Curtin Corrosion Centre, we follow a holistic approach to investigate mechanically assisted phenomena, which links the alloy’s microstructure to the observed failure mechanism. Enter to discover how our researchers contribute to understanding, managing, and controlling corrosion facilitated or initiated by mechanical processes.

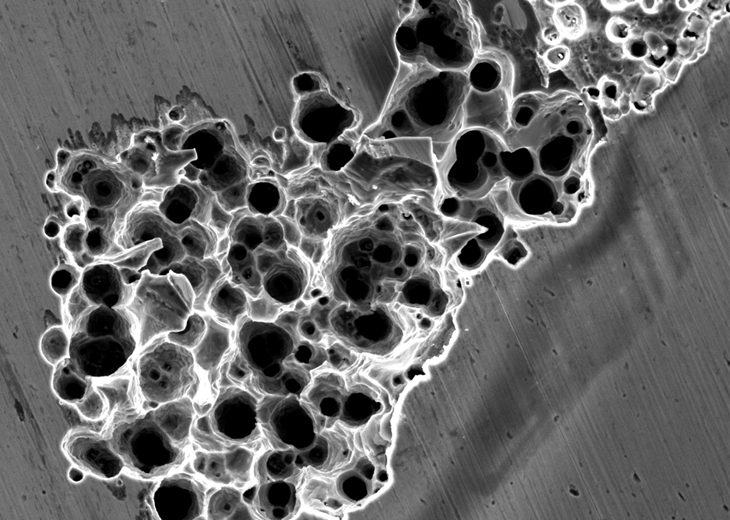

Localised Corrosion

Although passive metals and alloys such as stainless steels, nickel-, aluminium, and titanium-alloys often present extremely low corrosion rates, they are often susceptible to localized corrosion in the form of, e.g., pits and crevices. In a given environment, localized corrosion resistance is highly influenced by alloy microstructure, not just composition, making the study of localized corrosion phenomena challenging.

Our team of researchers has gained international recognition in the field of localized corrosion of corrosion-resistant alloys, including stainless steels, nickel- and aluminium-alloys. Enter to find out more about our approach to understand and prevent localized corrosion of engineering components.

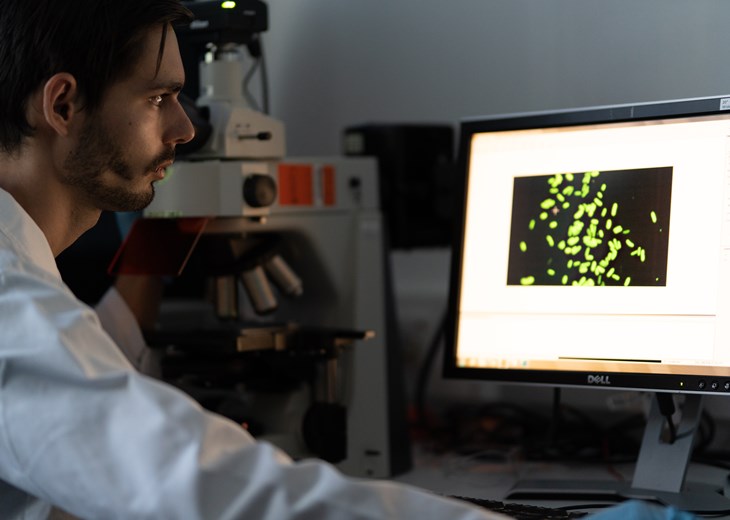

Microbiologically influenced Corrosion

Microbiologically influenced corrosion (MIC) is corrosion initiated, facilitated or accelerated by microorganisms and their metabolic functions. MIC is one of the most multidisciplinary fields in corrosion and material research, requiring corrosion, electrochemistry, microbiology, mathematics, modelling, and materials science competence. MIC affects many industries, including oil and gas, to defence, aerospace, infrastructure, and more.

The Curtin Corrosion Centre is at the forefront of MIC research globally. Enter to learn more about how our researchers tackle this complex challenge.

Corrosion Under Insulation

Corrosion under insulation (CUI) is an insidious form of corrosion caused by water entrapped within thermal insulation. Common to many industries, but particularly challenging in chemical and petrochemical plants, CUI represents about 10% of the total cost maintenance and repair budgets.

The Curtin Corrosion Centre is at the forefront of CUI research, engaging with industry on fundamental, detection, and prevention research. Enter to learn more about our approach at combating CUI.

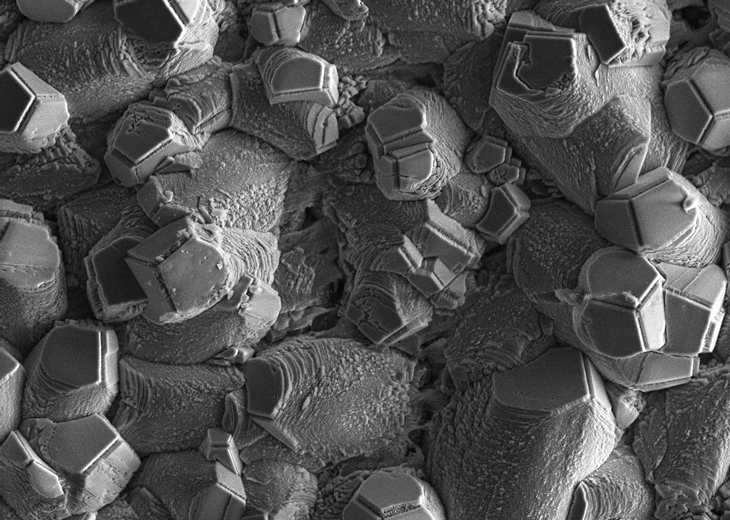

Acid Gas Corrosion

Dissolved acid gases such as CO2 and H2S can lead to complex corrosion behaviour. Under certain conditions, robust protective films form, reducing corrosion rates drastically. However, different forms of localised attack often occur when the protective scales breakdown or when unstable films precipitate. Moreover, HS is known to promote environmentally assisted cracking of carbon and low alloy steels as well as many corrosion resistant alloys.

Our researchers investigate all aspects of acid gas corrosion, from uniform corrosion modelling, corrosion prevention and monitoring, to environmentally assisted cracking. In this page, you will learn more about acid gas corrosion research at the Curtin Corrosion Centre.

Atmospheric Corrosion

Atmospheric corrosion is the most common corrosion phenomenon we experience in our daily lives. Atmospheric corrosion leads to the typical rust in outdoor exposures, but it can also result in catastrophic localised corrosion and mechanically assisted corrosion failures.

At the Curtin Corrosion Centre, we investigate the degradation of coatings and materials under simulates atmospheric conditions. Enter to discover our research and approach to atmospheric corrosion research.

Corrosion Protection

Even though the best approach to mitigate or eliminate corrosion risks is by selecting materials that will resist the most aggressive service conditions, this method might be cost-prohibitive in many situations. Corrosion protection strategies, thus, involve corrosion inhibitors, organic and inorganic coatings, as well as electrochemical protection.

The Curtin Corrosion Centre conducts acclaimed international research on corrosion inhibition, coating degradation and life modelling, as well as electrochemical protection and associated side-effects. In this page, you will discover how the Curtin Corrosion Centre is at the forefront of corrosion protection research.

Integrity Management

Integrity management is vital to safeguard the life of assets as well as to minimize health, safety, and environmental risks. Adequate integrity management strategies must be applied systematically to maintain valuable assets in working conditions, so they remain fit-for-purpose. Our subject matter experts at the Curtin Corrosion Centre provide optimal solutions to decision makers. In this page, you will learn more regarding our integrity management activities.

Integrity Management

Large-Scale Industrial Research

Supported on the combination of industry and scholarly experience our researchers and in collaboration with international industry partners, the Curtin Corrosion Centre designs, builds, and operates large-scale industrial processing plants, including a unique Mono-Ethylene Glycol (MEG) laboratory-scale regeneration and reclamation research facility as well as a world-first liquified natural gas (LNG) regasification unit.

Large-Scale Industrial Research