Microbially Induced Corrosion Laboratory

Overview

The Curtin Corrosion Centre has developed world-class capabilities for studying microbiologically induced corrosion (MIC) phenomena. By cooperation with several research centres at Curtin and around the world, the Curtin Corrosion Centre has been expanding its research and testing capabilities providing cutting-edge technology and state-of-the-art methods to study microorganisms and their effects on infrastructure and processes in the energy, water, and resources industries.

Our research typically involves transposing a field environment to a laboratory setting. We investigate how microbes respond to the changes in environmental conditions (e.g., aeration, temperature, pressure, shear stress) experienced through different areas in an industrial facility.

Biofilms

Once biofilms are formed on a metal surface, we can use electrochemical techniques to assess MIC rates and mechanisms and conduct ex-situ analyses to investigate biofilm structure, viability and composition, as well as corrosion products and surface profile.

Our research also focuses on the rate of biofilms formation as well as how biofilms interact with the environment. Our team assesses not only the effectiveness of chemicals treatments, such as corrosion inhibitors and biocides but also the impact of corrosion mitigation methods—including cathodic protection and coatings—on biofilm formation and biofouling. Chemical qualification and optimisation can be done at different conditions experienced in the field, such as in the presence of deposits and bacteria.

MIC facilities at Curtin

The Curtin Corrosion Centre offers a comprehensive array of state-of-the-art facilities and instrumentation to study the interaction of microorganisms and materials.

Infrastructure

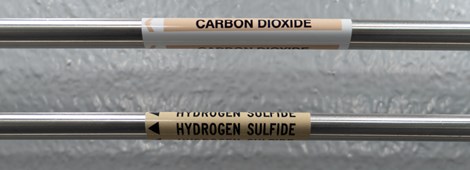

The MIC facilities include specialised MIC laboratories that comply with Personal Containment Level 2 (PC2).

Biofilm characterisation

Our molecular microbiology laboratory enables us to perform a variety of DNA-based and RNA-based analysis for characterisation of total and metabolically active populations in the sample. The state-of-the-art equipment includes:

- Enumeration of corrosion-related microbes by traditional cultivation methods.

- Quantitative PCR for enumeration of bacteria and archaea (qPCR).

- Measurement of Adenosine triphosphate (ATP) and metabolic activity.

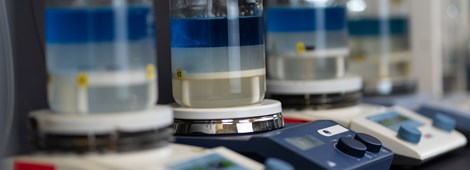

- Specialised MIC equipment and biofilm devices: CDC bioreactors, autoclaves, flow biofilm system with biostuds (flow rates up to 15 feet/s).

- Development of selective serial dilution media for monitoring of problematic microbes.

- Biofilm imaging and microscopy facilities: optical/phase contrast, confocal laser scanning microscopy (CLSM), fluorescence, scanning electron microscopy (SEM), 3D profilometry, uCT imaging.

- Advanced bioinformatics and statistical methods to assess microbial distribution and diversity across industrial facilities.

Conventional and advanced MIC research

The MIC test facilities are equipped with the same modern potentiostats/ galvanostats, glass cells and autoclaves, as well as specialised instrumentation that enable us to study the effects of biofilms on corrosion in situ and in real time. The list of essential tests and instruments includes:

- Comprehensive corrosion coupon and Biostuds analysis.

- MIC under deposits, galvanic, pitting and crevice testing in the presence of microbes.

- Corrosion and MIC inhibition and biofilm kill test studies.

- Chemical optimisation for biofilm and MIC inhibition.

- Evaluation of microbial adhesion and biofilm formation on metallic and non-metallic materials at various environmental conditions.

- Wire beam electrode (WBE) for studying the spatiotemporal electrochemical behaviour of metals under biofilms and deposits and the efficiency of corrosion and antimicrobial inhibitors.

Advanced materials characterisation

Through the John de Laeter Centre (JdL), the Curtin Corrosion Centre has access to a world-class microscopy facility. The tools we use more frequently to investigate bio-corrosion products and bio-deposits include:

- X-ray diffraction (XRD).

- SEM and energy dispersive X-ray spectroscopy (EDS).

- Raman and infra-red spectroscopy.

- Time-of-flight secondary ionisation mass spectrometry (TOF-SIMS).

The only bank of MIC microorganisms in Australia

The Curtin Corrosion Centre has developed a unique bank of microorganisms isolated from oilfields, corroded equipment, and deep seawater environments.

The bank is used for MIC and biofouling research and chemical qualification. We also have a variety of ASTM/DSM reference strains to study MIC phenomenon.

Serving Australian industries

The Curtin Corrosion Centre actively engages with industry to perform failure investigations and MIC risk assessment, and provide expert consultancy advice as well as peer-review of technical reports.

Our researchers conduct site visits and develop custom specialized protocols for field sampling of microbes and MIC related samples.