Seawater and Atmospheric Corrosion Laboratory

The new SEA-LAB

In 2019 the Curtin Corrosion Centre commissioned a new Seawater Laboratory, which is home to our new weathering test equipment and a dedicated section for short- and long-term corrosion, cathodic protection, and electrochemical research in natural seawater.

The state-of-the-art weathering equipment enables coatings and materials degradation studies under complex exposure cycles, which can be tailored to simulate specific field exposure situations. Whereas the seawater testing capabilities allow us to conduct research that is pushing the boundaries of corrosion resistant alloys, evaluate the mechanisms and kinetics of calcareous film formation, cathodic disbondment performance, and more.

Weathering equipment

The dedicated coatings and materials testing facility at the Curtin Corrosion Centre houses a brand new salt spray chamber and an environmental chamber, which can simulate specific outdoor atmospheric conditions. Accelerated weathering tests are used to compare and study the rates of degradation of various coatings and materials under complex environmental cycles addressing specific field service environments.

Tests can be done to simulate extreme temperature fluctuations, from -40 to 180 °C and ultra-violet (UV) light exposure. The Relative Humidity range is 20 to 100%

Our research also focuses on developing life prediction models based on a combination of electrochemical methods and changes in physical properties after long-term exposures.

The weathering system at the Curtin Corrosion Centre can comply with a long list of international standards. The most relevant are:

| ASTM | AS | BS |

|

ASTM B-117 |

AS 2331 method 3.1 AS 2331 method 3.13-A AS 2331 method 3.13-E AS 2331 method 3.2 AS 2331 method 3.3 |

BS 5466 P BS 7479 BS-EN-ISO 7253 BS-EN-60068-2-11 BS-EN-6052-11-6 BS-EN-60512-11-6 BS 2011 Part 2.1 BS 3900 F12 BS 5466 P1 BS 5466 P2 |

| DIN | ISO | Automotive & Additional |

| DIN 50 021 SS DIN 50 021 ESS DIN 50 021 CASS DIN 50017-KK |

ISO 3770 ISO 3768 ISO 3769 ISO 7253 ISO 9227 ISO 14993 |

BMW AA-0213 (AA-P224) BMW AA-0224 (AA-P 175) BMW AA-0324 (AA-P 184) CCT I (CCT A) CCT II (CCT B) CCT IV (CCT D) FIAT 50180 A FIAT 50180 A2 FIAT 50180 A3 FORD FLTM BI 103-01 GM 4298P GM 4465P JAGUAR JNS 30.16.03 JISH8502 M1 JISH8502 M2 JISH8502 M3 JIS Z 2371 MIL STD 202 MIL STD 750 1046.3 MIL STD 810G Renault D171058 RTCA/DO-160 VOLVO STD 6011,102 VG 95 210 method 101C |

Corrosion and cathodic protection in natural seawater

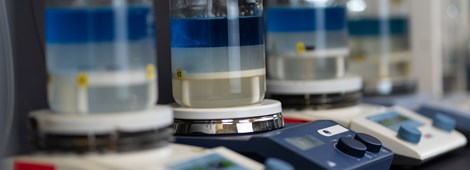

The SEA-LAB at the Curtin Corrosion Centre has a broad range of modern instruments to evaluate the performance of coatings and materials as well as the efficacy of chemical treatments in natural seawater and under simulated marine atmospheres and subsea operating conditions.

Tests in natural seawater provide an independent and comprehensive corrosion assessment of materials and coatings. The SEA-LAB is equipped for short- (typically up to 30 to 60 days) and long-term (often between 18 to 24 months) continuous measurements of electrochemical parameters such as corrosion potential, corrosion current (rate), and cathodic protection efficiency.

Our researchers regularly conduct long-term experiments in small (approximately 20 mL) or large (200 L) vessels, which can host a multitude of coupons and configurations. For example, the 200L tanks allow for potentiostatic (cathodic and anodic) tests on up to 24 independent samples simultaneously.

Materials are, thus, tested in natural seawater that can be regulated from 4°C to 100° within a 1°C range. The seawater can also be treated, e.g., flux regulation system, oxygen control, pollution, chemical treatments, etc.

The custom high-accuracy data acquisition systems can record up to 150 individual channels that can remotely be controlled and operated.

At a glance

The SEA-LAB offers:

- Tests in Australian natural seawater.

- Temperature control from 4°C to 100°C and treated.

- Complete and independent in-situ corrosion monitoring system for continuous measurements of electrochemical potential, corrosion currents (rates), and cathodic protection.

- Glass and glass-fibre reactors with volumes from 20 mL to 200 L. Larger volumes can be accommodated.

- Temperature regulation systems (water bath, cryostat, heating resistance)

- More than 150 channels for long-term data logging.

- Potentiostats/ galvanostats, including multi-channel units.

- Cathodic disbonding tests.

- Wet parking investigations.