Corrosion Under Insulation

A hidden problem

Corrosion under insulation (CUI) is an insidious form of corrosion caused by water entrapped within thermal insulation. In hot services, carbon steel pipes, tubes, and pressure vessels operating up to 175 °C may experience CUI; while those made of austenitic and duplex stainless steels might experience CUI between 50 and 175 °C. The presence of thermal insulation and jacketing slows down water evaporation and prolongs the wetting period. As a result, corrosion proceeds undetected.

The hidden nature of the CUI often makes accurate inspection and monitoring difficult. Usually, the detection of CUI can be too late; hence, resulting in disastrous outcomes such as leakages, loss of containment, and even fire and explosion. A study has shown that the petrochemical industry spends approximately 10% of the maintenance and repair budget for piping systems and pressure vessels in CUI alone.

The role of water and chlorides

The presence of water and corrosive species such as chloride ions are important factors determining the likelihood of CUI. Creating a water-tight system to avoid CUI is proven to be unreliable. Water eventually reaches the steel surface, creating an electrochemical corrosion cell with oxygen reduction being the dominant cathodic reaction. Therefore, designing insulated systems that do not retain water but instead facilitate the insulation to dry out can be the first step in mitigating CUI.

Further, CUI can be promoted by the presence of inherent chloride ions leached from the insulation or the external environment. Long-term exposure to high temperature may increase leachable chloride contents in certain insulation materials.

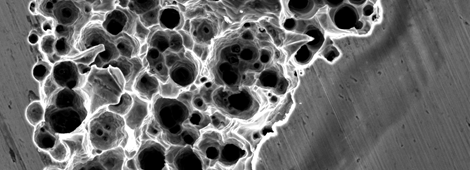

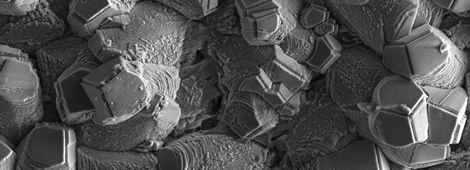

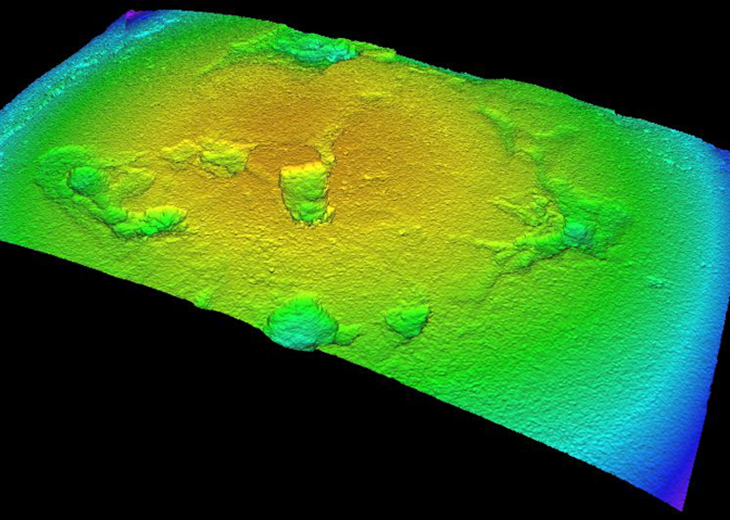

CUI manifests in various forms. Severe localised corrosion was found on bare carbon steel surface simulating areas with degraded coatings. On stainless steels, particularly austenitic grades, external stress corrosion cracking has been reported.

CUI research at Curtin

Curtin Corrosion Centre actively engages with industry on CUI studies. We investigate both the mechanism and the parameters that influence CUI. Additionally, we explore various promising CUI mitigation strategies, such as the appropriate selection of insulation materials, the use of high-temperature protective coatings, and chemical treatments.

Our experienced researchers and engineers have developed test protocols to study CUI in line with relevant industry guidelines; for instance, %water absorption, leachable ions contents, corrosion rate determined by weight loss, localised corrosion characterisation by 3D profilometry, in-situ monitoring for corrosion and insulation dry-out using electrochemical methods, and corrosion products characterisations. Access to advance corrosion test facilities enables the in-depth analysis of CUI mechanism, which further provides insight into CUI mitigation.