Microbiologically influenced Corrosion

Microbes and metals

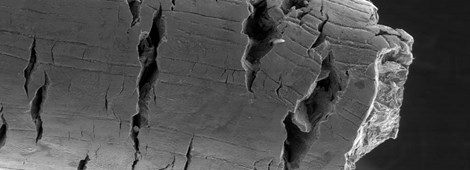

Microbiologically influenced corrosion (MIC) is corrosion initiated, facilitated or accelerated by microorganisms and their metabolic functions. MIC is one of the costliest forms of corrosion and remains highly unpredictable. MIC can lead to the fast, localized dissolution of a metal substrate at rates as high as 10 mm/y.

Biofilms

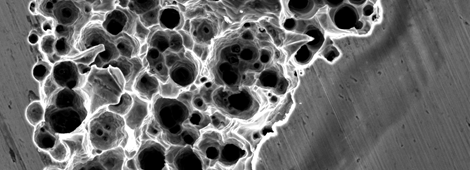

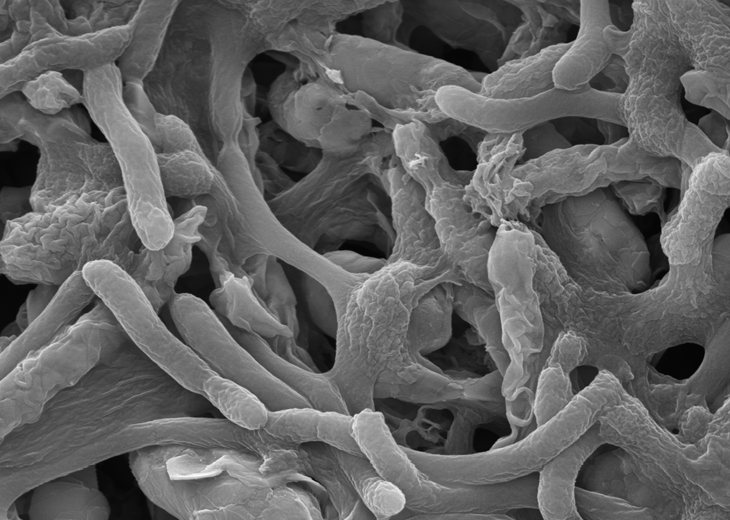

There is a scientific consensus that biofilm formation is the critical step in MIC. Biofilms consist of communities of microorganisms attached to the metal surface and embedded in self-produced extracellular polymeric substances (EPS) containing polysaccharides, proteins, lipids and extracellular DNA.

Any metal surface in contact with water is susceptible to biofilm formation. Once a biofilm is formed, it provides a physical barrier that protects microbes against biocides. It has been demonstrated that bacteria in biofilms (attached to the surface) can resist antimicrobial compounds at concentrations up to 1000 times higher than those active on the same bacteria in the fluid. Biofilms on metallic surfaces are dynamic, continually changing in response to inhibitor/biocide compounds, which typically result in enhanced resistance of the microorganisms to chemical treatments. The more mature a biofilm is, the more challenging to eradicate. For this reason, MIC mitigation is difficult and costly and drives a worldwide market for microbial control that is worth billions of dollars annually.

MIC research at Curtin

The Curtin Corrosion Centre has developed expertise and world-class, state-of-the-art, MIC laboratories and staff to provide high-end technology and methods to study microorganisms (mainly biofilms!) and their effects on metallic infrastructure and processes in the resources sector.

The multidisciplinary MIC team has developed fruitful collaborations with industry groups that have resulted in more than 40 funded projects valued at approximately AU$3M in the past 4 years.

The Curtin Corrosion Centre’s unique approach combines expertise in microbiology, materials, and corrosion science to investigate MIC mechanisms and help the industry understand and manage the risk of MIC. Through fieldwork and close collaboration with industry, the Curtin Corrosion Centre has established the first bank of microorganisms containing at least 50 different species from Australian oilfields.

Our research typically involves transposing a field environment to a laboratory environment. We can study how microbes respond to changes in environmental conditions (e.g., aeration, temperature, pressure, shear stress) experienced through different areas in an industrial facility.

Once biofilms are formed on a metal surface, we can use electrochemical techniques to assess MIC rates and mechanisms and conduct ex-situ analysis of test metals to investigate biofilm structure, viability and composition as well as corrosion products and surface profile. We can also study how fast biofilms form on different substratum materials.

Our team has developed a unique expertise in the assessment and optimisation of chemical treatments against sessile microorganisms (biofilms) formed on different types of materials. We have widely used several in-situ and ex-situ techniques to study biofilms and its inhibition under different scenarios. For instance, the team has studied the effect of deposits, nutrients and temperature on the risk of MIC in carbon steel. In particular, the role of bacteria on under-deposit corrosion (UDC) of carbon steel is one of the major areas the team has investigated. These include research on corrosion inhibitor and biocide performance in the presence of complex deposits formed in the occurrence of both biofilms and deposits. We have also conducted investigations to accurately define the frequency of treatments and dosages to ensure chemical treatments are effective and to identify persistent microorganisms that develop tolerance to chemical treatments.

Training and education

Training and education are paramount to address MIC. The Curtin Corrosion Centre provides training, hands-on laboratory sessions, and MIC workshops. MIC is one of our core courses in the various Corrosion Graduate programs.