Facilities

EXTREME Laboratory

The EXTREME Laboratory was developed to address the steady demand for materials research in sweet and sour environments as well as pure hydrogen gas.

The only one of its kind in Australia, the EXTREME Laboratory at the Curtin Corrosion Centre enables research under high-pressure and high-temperature pure hydrogen sulfide, carbon dioxide, and specialise gas mixtures. Additionally, the facilities allow our researchers to perform hydrogen embrittlement and microbiological tests in hydrogen gas atmospheres. Enter to discover the diverse testing and research capabilities at Curtin University.

Environmentally Assisted Cracking Laboratory

The environmentally assisted cracking laboratory (EAC-LAB) at the Curtin Corrosion Centre houses state-of-the-art equipment for the study of diverse forms of EAC such as stress corrosion cracking, hydrogen (induced) stress cracking, corrosion fatigue, fracture mechanics based evaluations, and more. Likewise, the EAC-LAB also allows hydrogen permeation and advanced electrochemical testing. In this page, you will learn more about our world-class EAC capabilities.

Environmentally Assisted Cracking Laboratory

Seawater and Atmospheric Corrosion Laboratory

The SEA-LAB at the Curtin Corrosion Centre enables us to push the boundaries of conventional stainless steels and nickel alloys, study coating degradation during complex weathering exposure cycles, investigate the formation of calcareous deposits, conduct long-term wet-parking research, optimize cathodic protection, rank coatings based on their cathodic disbondment resistance, and more. Enter to learn more about the SEA-LAB and the broad range of testing capabilities it offers.

Seawater and Atmospheric Corrosion Laboratory

Microbially Induced Corrosion Laboratory

Curtin Corrosion Centre's microbiologically induced corrosion (MIC) expertise and test facilities are among the best in the world. The MIC laboratories are equipped with state-of-the-art instrumentation for microbiological and biofilm characterisation. Our equipment enables fundamental and applied research on the interaction between microbes and materials, including in situ and real-time analyses.

Our investigators have pioneered DNA and RNA-based methods to identify only those microorganisms associated with MIC. The Curtin Corrosion Centre also developed the first bank of MIC-causing bacteria. In this page, you will discover the tools and techniques we use in our leading MIC studies.

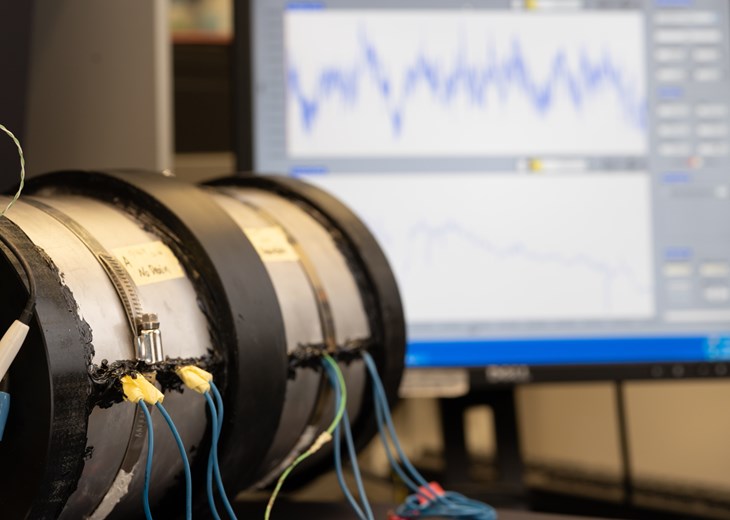

Corrosion Under Insulation facilities

The Curtin Corrosion Centre is home to unique corrosion under insulation (CUI) test facilities. The CUI test rigs developed in house enable us to evaluate insulation materials, CUI severity, in situ monitoring of wet-dry-cycles and corrosion rates and mechanisms, and quantify the risk of CUI under simulated field conditions.

Enter to discover the Curtin Corrosion Centre facilities and abundance of test methods for understanding, monitoring, managing, and reducing the impact of CUI.

Advanced Electrochemical Testing

Conventional and advanced electrochemical testing is one of our core areas of expertise. The Curtin Corrosion Centre offers an impressive array of modern equipment capable of conducting a plethora of corrosion methods, from simple corrosion potential monitoring to polarization experiments, electrochemical impedance spectroscopy, zero resistance amperometry, electrochemical noise, Mott-Schottky analysis, and more. Enter to discover the Curtin Corrosion Centre capabilities supporting cutting-edge corrosion research.

Advanced Electrochemical Testing

Corrosion Inhibitor Testing

Corrosion inhibitor research and testing facilities at the Curtin Corrosion Centre enable thorough corrosion inhibitor evaluations, ranging from corrosion rate measurements to compatibility testing. The Curtin Corrosion Centre aims to evaluate and improve the mitigation strategies currently used in conventional industry practices.

Here, you will discover the broad range of corrosion inhibition methods we use at the Curtin Corrosion Centre to determine the performance, mechanisms, and compatibility of chemical treatments.

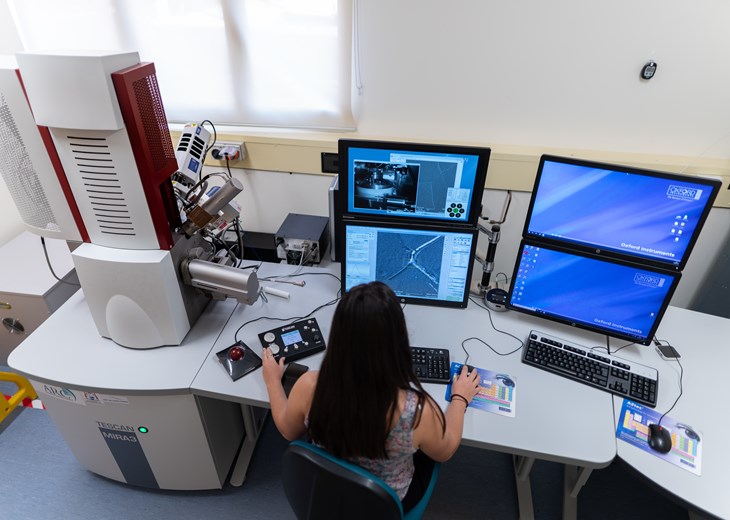

Advanced Materials Characterisation

Curtin corrosion centre researchers have access to the world-class characterisation facilities at the John de Laeter Centre (JdLC), Curtin’s centralised research infrastructure hub. In this page, you will learn about the state-of-the-art instruments and techniques we use for corrosion and materials research.

Advanced Materials Characterisation

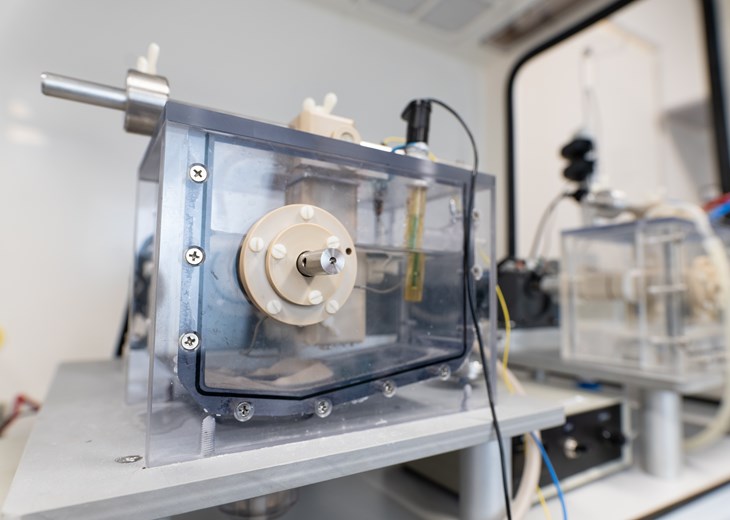

Tribocorrosion

In collaboration with the School of Civil and Mechanical Engineering, the Curtin Corrosion Centre developed state-of-the-art test rigs to study different tribocorrosion phenomena, relevant to the resources industry as well as to biomedical corrosion research.

The Tribocorrosion Laboratory enables cutting-edge biomedical corrosion research. Enter to discover more about our tribocorrosion test facilities.

Large-Scale Industrial Testing

The Curtin Corrosion Centre owns and operates the only Mono-Ethylene Glycol (MEG) laboratory scale regeneration and reclamation research facility in Australia. The system simulates a full industrial MEG regeneration loop from condensate/MEG separation, divalent cation removal through pre-treatment, regeneration by distillation and either full or slip-stream vacuum reclamation for dissolved salt removal. The system allows the simulation of any potential field fluid composition and operational condition, to study and improve industrial plant operation and diagnose operational issues occurring in the field.

Find out more about the demand-driven research on the MEG regeneration and reclamation research pilot plant.