Tribocorrosion

Overview

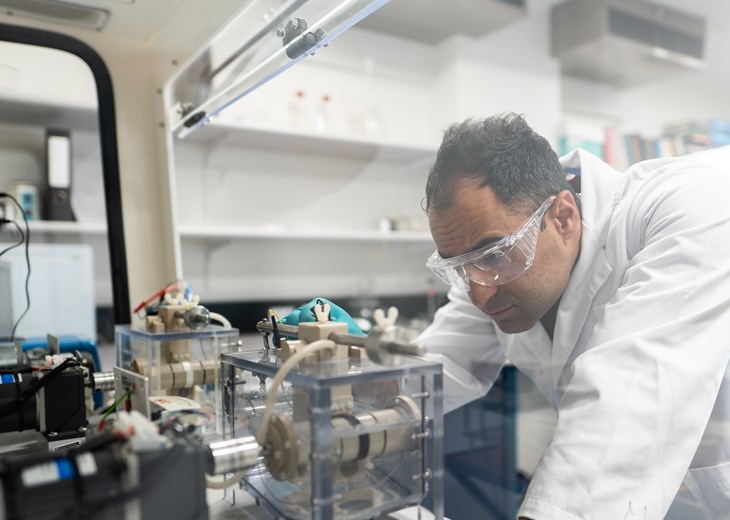

In collaboration with the School of Civil and Mechanical Engineering, the Curtin Corrosion Centre developed state-of-the-art test rigs to study different tribocorrosion phenomena, relevant to the resources industry as well as to biomedical corrosion research.

A broad range of industries and applications

The Tribocorrosion Lab offers a unique three-body abrasion-corrosion setup that was designed to study wear-resistant alloys used in slurry pumps (mining and mineral processing) and sliding bed CO2 tribocorrosion (oil and gas). In this configuration, the sample is loaded against a rotating rubber counter-face while different abrasive particles (e.g., silica sand) are delivered. Tests can be carried out in the presence of different corrosive conditions and at up to 60 °C, under different applied loads.

For general purpose abrasive wear ranking of engineering alloys, an ASTM G65 dry sand rubber wheel (DSRW) is available. Coefficient of friction of surfaces can be measured using pin-on-disc and reciprocating test rigs. At the Department of Mechanical Engineering, roughness measurement can be performed using a standard Talysurf.

Cutting-edge biomedical research

The equipment in our Tribocorrosion Lab can also be used to study dynamic crevice tribocorrosion, in conditions that simulate, e.g., scenarios encountered in total hip joint replacements. The purposely made ring-on-plate tribo-electrochemical test rig can monitor intermittent micro-movements and the associated passive film breakdown and repair. The tribo-electrochemical data is collected using an advanced SP300 Biologic potentiostat and a customised oscilloscope.