Concrete corrosion research

Concrete is the most widely used construction material, and twice as much concrete is used as all other industrial materials (i.e., wood, steel, plastic, and aluminium) combined due to its low cost, versatility, and durability. Reinforced concrete (RC) has been used with outstanding success in various civil infrastructures, such as tunnels, bridges, marine structures, sewer systems and water retaining structures. The in-service durability of RC structures can be compromised due to the frequent exposure to aggressive environments triggering various deterioration processes. Deterioration of RC predominantly occurs due to the (a) degradation of concrete and (b) corrosion of steel reinforcement. These deterioration mechanisms could occur in isolation or at the same time.

Take a look at this video, which summarizes the construction and commissioning of our first concrete corrosion cells.

Corrosion of the reinforcement steel in RC structures ultimately leading to structural deterioration is a lengthy and complicated process where several interrelated parameters interact. Hence, predicting and monitoring concrete corrosion in the laboratory and the industrial application is not straight forward. For example, in marine structures, chloride-induced corrosion poses a serious threat. It has been extensively studied with no clear consensus on specific corrosion mechanisms due to a wide range of variables selected for the study.

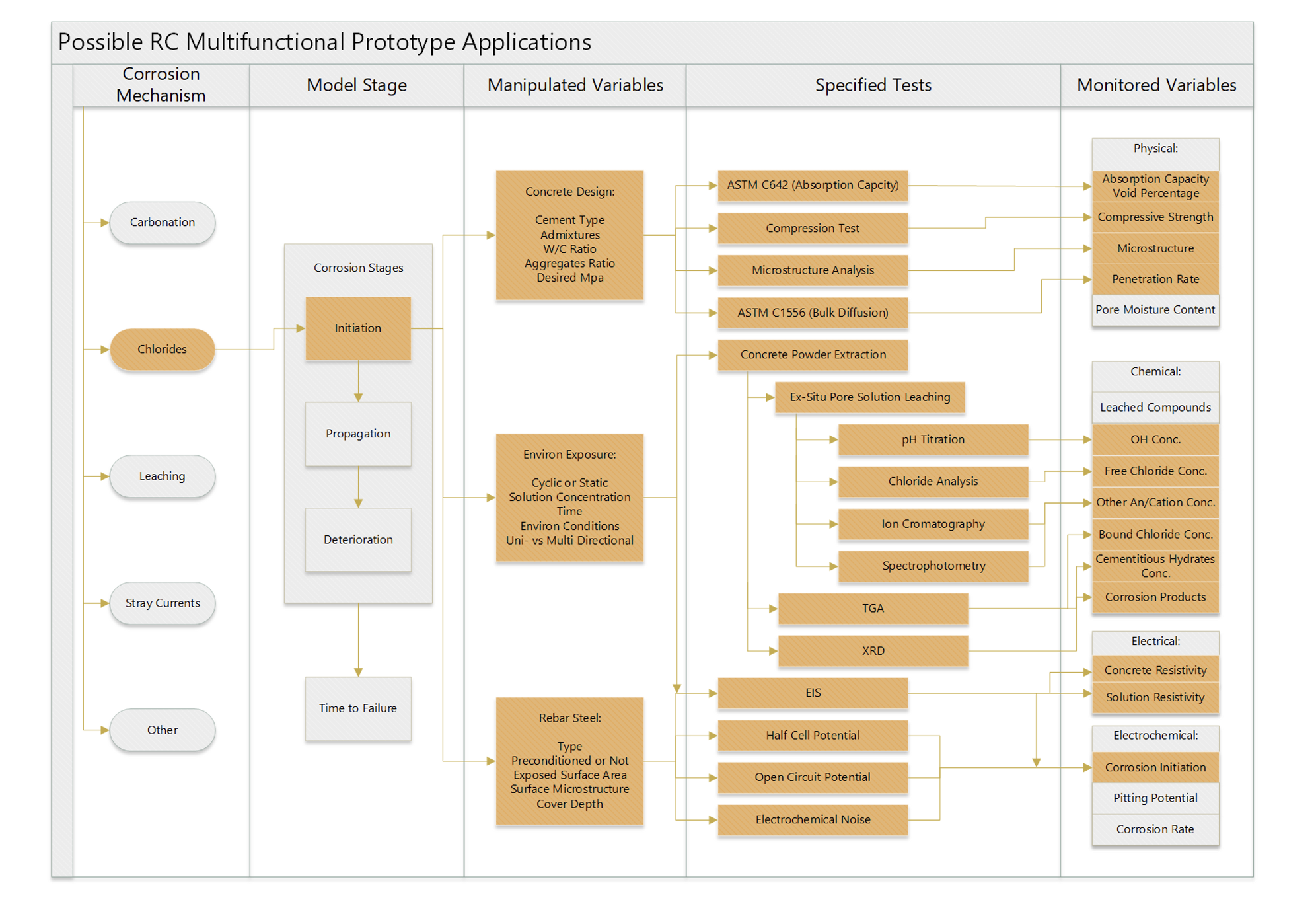

At the Curtin Corrosion Centre, in collaboration with Curtin Civil Engineering, Curtin Mechatronics Engineering and Vinsi partners, we have developed a multifunctional concrete corrosion prototype and testing protocols to monitor and assess the various environmental influences on chloride-induced RC degradation to predict corrosion initiation, propagation, and deterioration. Key aspects chosen for initial studies include electrochemistry, chloride penetration (including diffusion and binding), and pore solution chemistry to establish a prediction model for chloride-induced corrosion. From the developed prototype, testing protocols and model, other corrosion processes can be studied in the future and the testing of various concrete remediation techniques and their effectiveness on lifetime extension of RC.

Possible applications of the new concrete corrosion facilities.

The development of the prototype includes concrete mix design and material selection, concrete casting and curing, specimen sealing and preparation for exposure conditions, and a specified exposure regime. Alongside the prototype specimens, cylinder moulds were cast for the more destructive tests such as compression and pore solution extraction. Electrochemical tests conducted include Electrochemical Impedance Spectroscopy (EIS), Open Circuit Potential (OCP), and Electrochemical Noise (ECN). Concrete and pore solution chemistry tests showing chloride diffusion include Ion Chromatography, Spectrophotometry and pH titration of the pore solution, as well as TGA and XRD on extracted concrete powders over the exposure period.

Simultaneously in collaboration with Curtin mechatronics engineering and Innovation Central Perth, a selection of sensors will be used to monitor conditions within RC such as chloride ion concentration, pH and conductivity. The results obtained will be compared to that of the testing explained above to validate the sensor readings.