Nutrient level determines biofilm characteristics and the subsequent impact on microbial corrosion and biocide effectiveness

Overview

The impact that nutrient level has on biofilm characteristics, biocide effectiveness and the associated risk of microbiologically influenced corrosion (MIC) were assessed using multispecies biofilms from two different oilfield consortia. This investigation demonstrated that the continuous flow of nutrients for the microbial growth resulted in higher activity, thickness and robustness of the biofilms formed on carbon steel, which induced greater localised corrosion compared to biofilms formed under batch, nutrient-depleted conditions. Additionally, it was shown that nutrient replenishment also impacted the effectiveness of the biocide in controlling microbial populations. The dissimilarities found in the biofilms developed on metals exposed to different nutrient regimes provided valuable information about the variation expected in microbial communities throughout oil production facilities, which should be accounted for when assessing the risk of MIC and for establishing MIC mitigation and monitoring strategies.

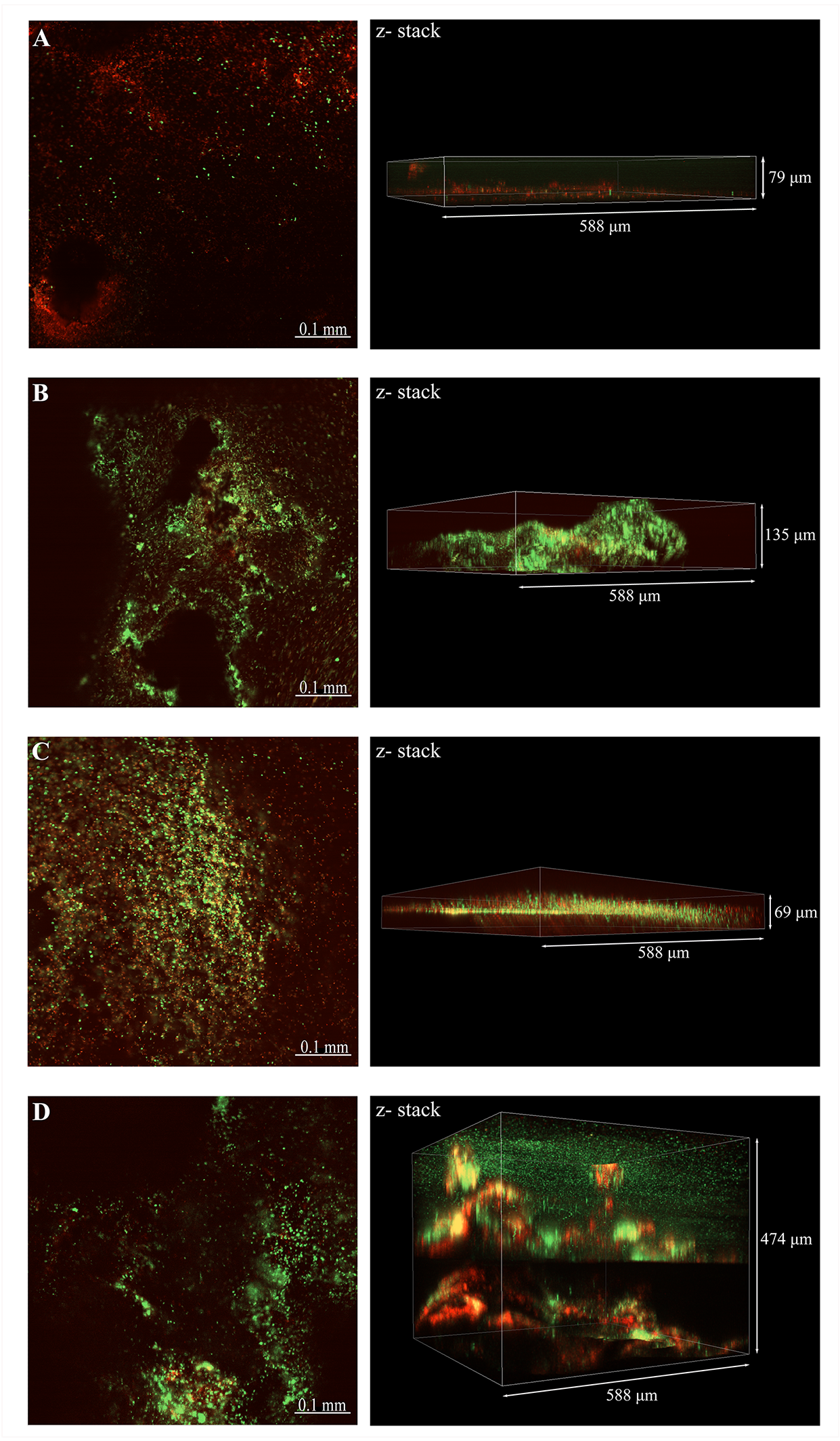

Figure 1; CLSM images of biofilms formed over carbon steel coupons at different nutrient conditions. (A) consortium 1 at batch conditions; (B) consortium 1 with continuous replenishment; (C) consortium 2 under batch conditions; (D) consortium 2 with continuous replenishment. Live cells, green stain; dead cells, red stain.

Objectives

This investigation aimed to identify changes in biofilms in response to nutrient level and to examine how these changes influence the severity of MIC and the effectiveness of glutaraldehyde, a chemical biocide commonly used to prevent MIC in the industry.

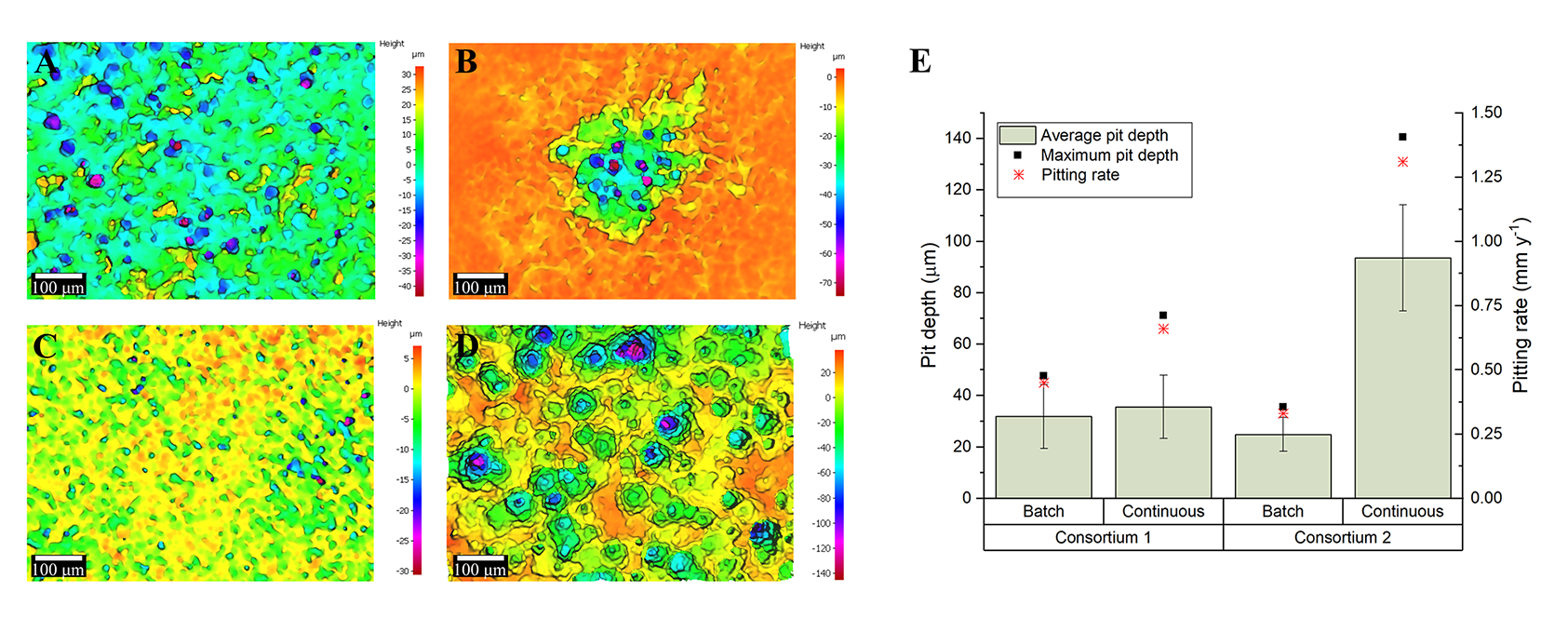

Figure 2; Localized corrosion analysis of carbon steel coupons exposed to different nutrient conditions. (A to D) 3D optical microscope surface images of carbon steel coupons. (A) consortium 1 under batch conditions; (B) consortium 1 with continuous replenishment; (C) consortium 2 under batch conditions; (D) consortium 2 with continuous replenishment. (E) Average pit depths and pitting rates calculated from the maximum pit depth. Error bars represent standard deviations of 10 deepest pits found in three independent replicates.

Why is it important?

Microbiologically influenced corrosion (MIC) is a complex process that generates economic losses to the industry every year. Corrosion must be managed to prevent a loss of containment of produced fluids to the external environment. MIC Management includes the identification of assets with higher MIC risk, which could be influenced by nutrient levels in the system. Assessing biofilms under different nutrient conditions is essential for understanding the impact of flow regime on microbial communities and the subsequent impact on microbial corrosion and on the effectiveness of biocide treatment. This investigation simulates closely oil production systems, which contain piping sections exposed to continuous flow and sections that remain stagnant for long periods. Therefore, results reported here are useful for MIC management and prevention. Moreover, the complementary methodological approach applied in this investigation highlighted the importance of implementing RNA-based methods for better identification of active microorganisms that survive stress conditions in oil systems.

Get the paper!

Citation

S.J. Salgar-Chaparro, K. Lepkova, T. Pojtanabuntoeng, A. Darwin, L.L. Machuca, Nutrient level determines biofilm characteristics and the subsequent impact on microbial corrosion and biocide effectiveness, Applied and Environmental Microbiology Mar 2020, 86 (7) e02885–19; DOI: 10.1128/AEM.02885–19.