Use of electrochemical current noise method to monitor carbon steel corrosion under mineral wool insulation.

Overview

Corrosion under insulation (CUI) is a challenging and costly problem for many industries. Because of the hidden nature, CUI damage cannot be easily detected. In this work, the electrochemical current noise (ECN) method was proposed as a tool for in-situ CUI monitoring, and the corrosion of bare steel under mineral wool insulation was studied. Intensities of corrosion were validated using gravimetry, and the form of corrosion confirmed using optical microscopy.

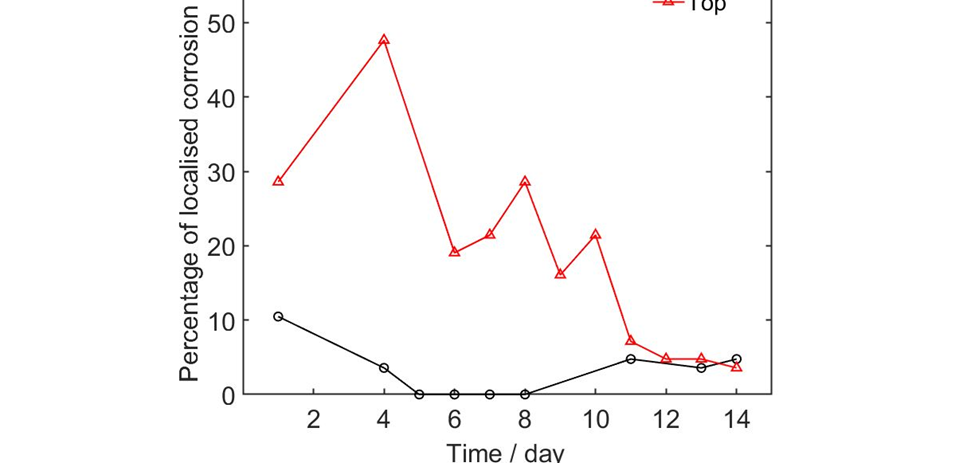

The standard deviation (SD) of the current noise signal was demonstrated as a reliable indicator of the degree of corrosion under mineral wool insulation. Recurrence quantification analysis was used to extract feature variables from ECN signals, which were later used to develop a random forest model to identify the type of corrosion, i.e., uniform or localised corrosion. The trained model was successfully applied to predict the extent of localised corrosion associated with mineral wool insulation.

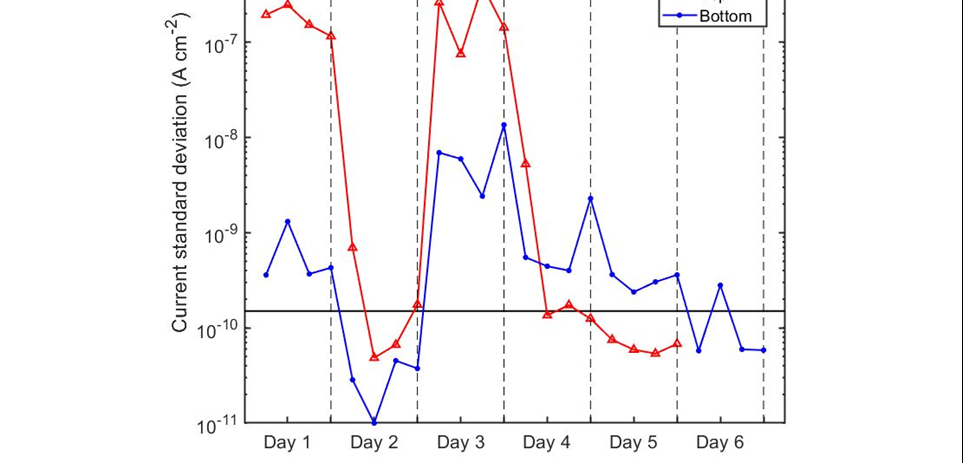

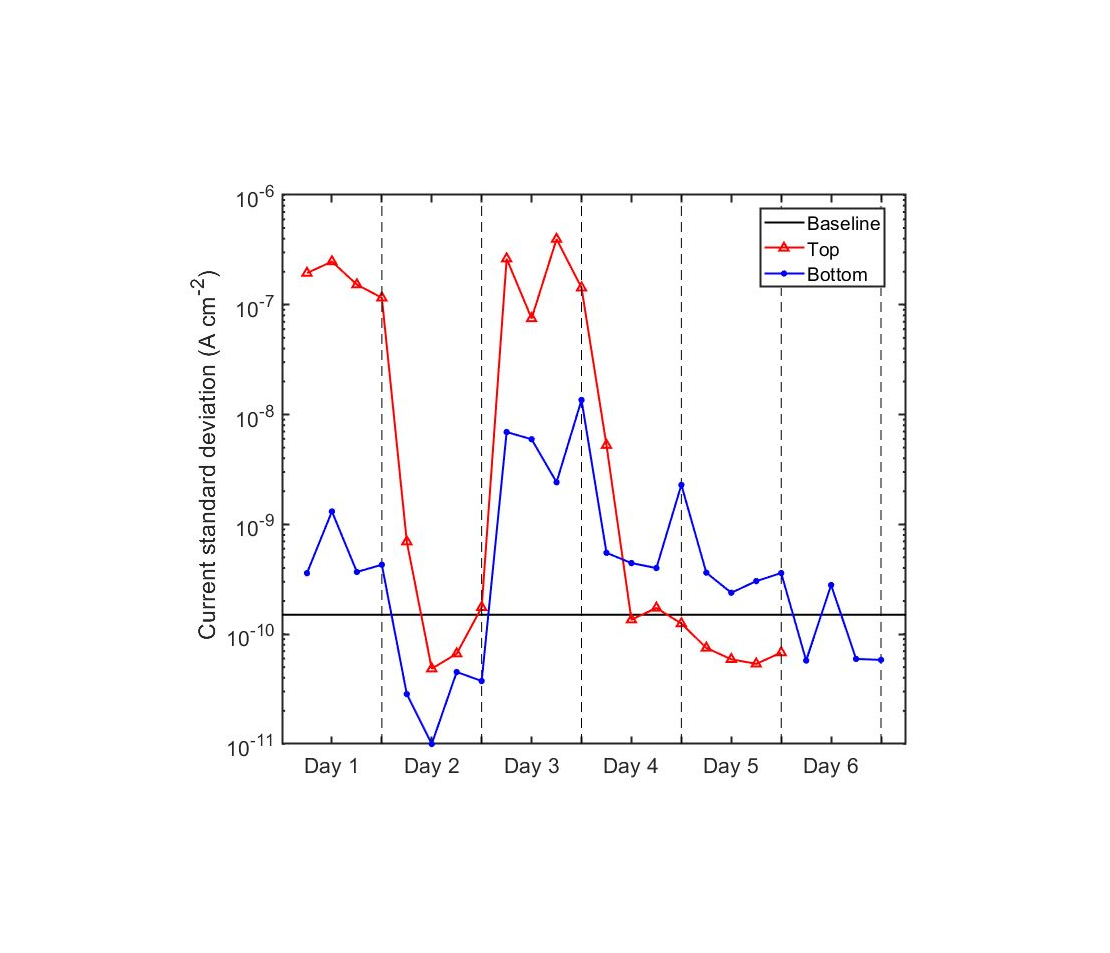

Figure 1. Current standard deviations obtained from two wet/dry cycles with mineral wool insulation without jacketing. Horizontal line indicates the dry condition baseline. Values above the baseline indicate wet condition with corrosion activities, while those at or below the baseline suggest dry condition and without corrosion activities.

Objectives

The objective of this work was to evaluate the use of the ECN method for real-time CUI monitoring. Herein, ECN was measured with a custom-built sensor comprising two identical half-ring steel samples. The SD of the measured ECN data was correlated with the wet/dry condition and the severity of corrosion under different experimental variables. Additionally, a random forest (RF) model was developed for detecting localised CUI. The potential of ECN and RF methods for CUI monitoring was discussed.

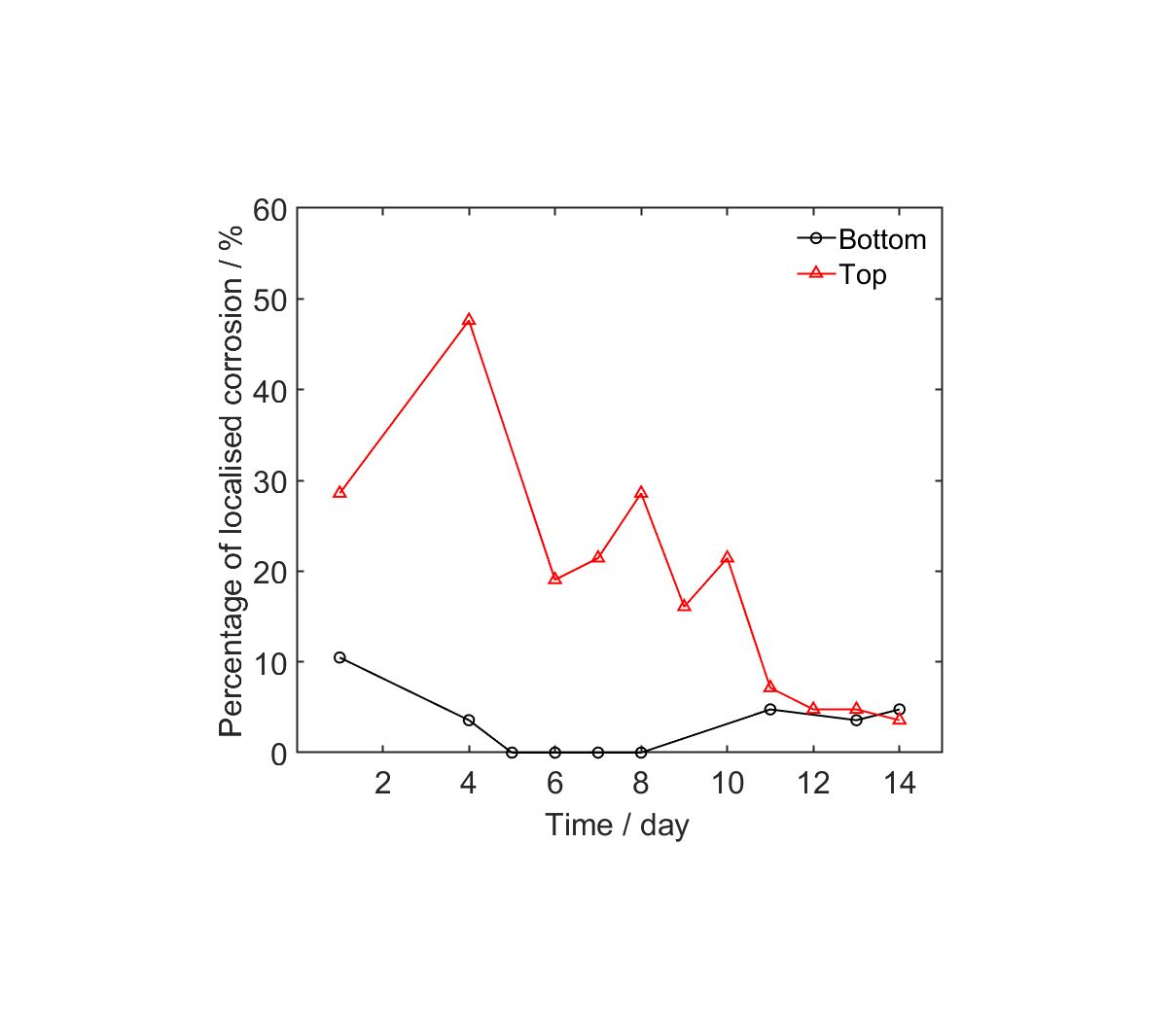

Figure 2. Percentage of ECN data predicted by the RF model as localised corrosion for both top and bottom samples under mineral insulation with the addition of corrosion inhibitor. This figure implies that the top section suffered from a greater extent of localised corrosion attack than the bottom section.

Why is it important?

The use of ECN data to detect insulation dry-out and the application of the RF model to predict the forms of corrosion were shown to be promising tools for in situ CUI monitoring. The methodology proposed in this work is capable of improving the efficiency of risk-based inspection programs by increasing the hitting rate of truly active CUI sites. Improving the efficacy of current tools is particularly useful when the sites susceptible to CUI are hard to access, and no other non-destructive testing (NDT) method could be implemented.

Get The Paper!

Citation

Hou, Y., Pojtanabuntoeng, T. & Iannuzzi, M. Use of electrochemical current noise method to monitor carbon steel corrosion under mineral wool insulation. npj Mater Degrad 4, 39 (2020). https://doi.org/10.1038/s41529-020-00144-3